The GPR Probe

“Since incorporating the Kalrez® O-ring, we have continued to receive outstanding field reports of flawless performance with the GPR™. And we have thousands of units in service throughout the world,” Don Mayeaux, CEO A+ Corporation

“Since incorporating the Kalrez® O-ring, we have continued to receive outstanding field reports of flawless performance with the GPR™. And we have thousands of units in service throughout the world,” Don Mayeaux, CEO A+ Corporation

During its long journey from well to consumer, natural gas can accumulate contaminants including moisture, sulphur, and chemicals left over from the production process. These can affect purity and thermal quality. Gas is sampled and analysed using a gas-extraction instrument such as the GENIE® Probe Regulator™ (GPR™) developed by A+Corporation, Gonzales, Louisiana.

Chemical resistance and mechanical sealing

In this harsh chemical, high pressure environment, the extracted sample must be free from entrained liquids such as condensed hydrocarbons, amines, and glycols which could harm the analyzing equipment or contaminate the sampling process.

GPR™ utilizes Kalrez® Spectrum™ 6375 O-rings to provide a liquid- and gas-tight seal in the foot valve whenever the probe is extracted.

side link to Kalrez Spectrum 6375 Data Sheet

How the GPR probe works

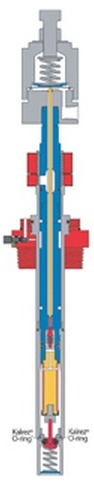

The GPR™ probe is inserted into the pipeline to capture a sample from the gas stream. Gas enters the probe through a spring-loaded foot valve assembly at the bottom of the unit. From there, it passes through a special membrane filter system and then through the built-in pressure regulator of the GPR™. The membrane filter is designed to reject the liquid hydrocarbon content of the gas at line pressure and temperature and to remove any other contaminants present in the pipeline gas, including liquid glycol and amines.

DuPont™ Kalrez® Provides Critical Sealing in Foot Valve

The foot valve at the lower end of the probe (see diagram) controls the entry of pipeline gas into the GPR™ and liquids rejected by the filter/membrane to gravity-flow back into the gas stream. The O-ring on this foot valve must provide a positive liquid- and gas-tight seal whenever the probe is extracted for servicing the membrane. Because of the harsh chemical environment produced by the pipeline, engineers at A+Corporation required an O-ring made from a chemically inert material that would complement the record of the GPR™ for unquestioned sealing performance and yet permit its use in a broader range of applications.

While fluoroelastomer and neoprene O-rings were effective, Don Mayeaux credits the superior performance of Kalrez® Spectrum™ in the foot valve to its outstanding combination of chemical resistance and mechanical sealing properties.

“Since incorporating the Kalrez® O-ring, we have continued to receive outstanding field reports of flawless performance with the GPR™. And we have thousands of units in service throughout the world,” he said. “ Kalrez® O-rings also have significantly expanded GPR™ service compatibility beyond natural gas pipeline applications.”

Variables such as the fat content of the food, time, temperature and the extent of contact between food and rubber can cause chemicals from the rubber to leach in to the food. Lubricants for machine parts and equipment can carbonise or burn, react with steam or caustic cleaners.